The Bioconvergence Paris Biofoundry

The concept of Biofoundry is at the heart of what is called the 4th industrial revolution, which aims in the next 30 years to replace industrial manufacturing with biological manufacturing in all sectors: this is called the “ Made by Biology ”. Synthetic biology is a discipline of biological engineering that aims to design and manufacture new biological systems: new enzymes, genetic circuits, tissues, even organisms. Why? Either to answer fundamental questions in biology, or to create artificial systems for particular biological applications.

The synthetic biology market is gigantic: it is estimated at 3,500 billion dollars by 2030-2040, of which one third for agri-food, one third for health, one third for other applications. In synthetic biology we are beginning to see applications, in particular startups, for example synthetic spider silk fabrics, bio-concrete, cellular agriculture, but also in health and immunotherapy: programming of lymphocytes to treat cancers, personalized medicine (microbiota engineering), vaccines, production of active molecules by biology.

What is a Biofoundry?

The person who designs a house is not the same who builds it; however, in biology this is currently the case.

A Biofoundry makes it possible to decouple the construction phase from the more intellectual phases: basically, we get humans out of repetitive and tedious tasks, and we do them in a more reproducible, faster and cheaper way. Humans will be able to focus on the more intellectual tasks: conception, design, computer-aided data analysis.

Today, there are about thirty biofoundries in the world, but none in France. The construction of the Biofonderie Paris Bioconvergence will meet the following needs:

- Accelerate the structuring of the bioengineering sector: all startups and labs do synthetic biology in a very artisanal way, without having access to equipment that is often very expensive. The objective is to put this equipment at the service of academic, industrial and start-up labs.

- Have a training structure for future engineers and researchers to introduce them to this way of building in biology

- Being an engine of innovation: it allows startups or even large industrial partners to obtain their proof of concept to succeed in their fundraising afterwards.

The first Green Biofoundry in the world

The idea of a biofoundry is to replace conventional oil refineries with biorefineries, which produce biomolecules fueled by biomass. One of the key points concerns the supply of biomass to grow bacteria and yeasts in biofoundries, which of course comes from agriculture. In a context where there are already 8 billion of us and we do not know how we are going to increase agricultural production to feed this population, Stéphane Lemaire has decided to take a different approach: he targets a method of bioproduction which is not based on classic frames but on microalgae, which can directly use CO2 and solar energy to produce the same type of molecules as the other chassis. The Paris Bioconvergence Biofoundry will therefore be the first Green Biofoundry in the world.

Transmission electron micrograph of a section through a single Chlamydomonas reinhardtii flagellate green alga. Chlamydomonas reinhardtii is a unicellular (single-celled) organism used as a model system in molecular genetics work and flagella motility studies.

Who does the Biofoundry work with?

On the one hand, with academic laboratories, which will be able to carry out larger-scale and more ambitious projects, therefore making it possible to obtain international funding which they did not have access to before. But also with industrial partners. The idea is to make public-private partnerships to develop strains, enzymes, processes, generate shared IP and therefore public-private R&D projects.Innovation is a fundamental aspect of biofoundry: its use will make it possible to file patents and licenses, but also to incubate startups and allow them to prove their concept to raise funds. The idea is to have a dedicated space, a project hotel where people can come for a short time, and for a very low cost, to take advantage of the platform and obtain their proof of concept.

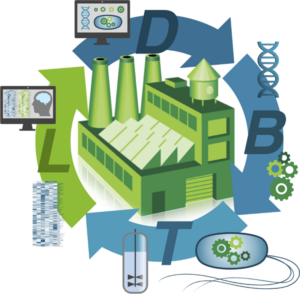

Design, Build, Test, Learn

Construction in biology today is very manual and artisanal; it’s long, it’s tedious, there are lots of biases, it’s very expensive and we make plenty of mistakes. And yet we have to test a lot of combinations because our predictive models are not good. When an architect builds a bridge, he doesn’t need to build 50 to select the one that will stand, and throw the others away! But in biology, that’s what we do: we don’t know which design will work in advance. We therefore need to improve our predictive models to be able, one day, to build a single working design.

Hillson, N. et al. Building a global alliance of biofoundries. Nat Commun 10, 2040 (2019).

The idea is to use computer-aided design, based on digital models, for the Design of biological systems; the construction (Build) will be completely automated by robots, without any human intervention. That way we can generate a hundred strains a week, and test them.

The Test phase will be carried out at the highest possible throughput, therefore thanks to microfluidics, FACS, high throughput imaging; but also with analyses at less high throughput, such as -omics analyses: this is why the platform will be equipped with tools for proteomics and metabolomics.

It will then be necessary to be able to analyze the enormous amount of data generated by these analyses: this is the Learn phase. Machine learning and artificial intelligence, coupled with statistical models, will help to make sense of the data, but also to improve the models used during the Design stage of the following cycles. We therefore enter a virtuous cycle that improves with each iteration.

A Distributed Biofoundry

The Biofonderie Paris Bioconvergence is divided into several parts.

Biofonderie Sorbonne Université

The Sorbonne University Biofoundry is the heart of this system, where DNA is made (regardless of the applications behind it) on bacteria, yeast and microalgae cells. Application examples:

- assembly of chromosomes or whole genomes (genomes from scratch)

- construction of genetic circuits

- enzyme building

- metabolic engineering for bioproduction

But also production of bioplastics, bank of biobricks, development of standardized databases, predictive models based on AI…

Stéphane Lemaire

in charge of the Biofonderie SU and research director in the laboratory of Systems and Synthetic Biology of Microalgae at IBPS

Pascal Hersen

in charge of the mammalian cells platform and Research Unit Director of Physical Chemistry Curie (UMR168)

Mammalian cells platform

The Biofonderie Paris Bioconvergence site dedicated to mammalian cells is located at the Institut Curie. This platform, evidently leaning towards applications against cancer, will use the DNA produced in the Biofoundry of Sorbonne University to modify at high speed and test cells.

The Industrial Biofoundry

Genopole is developing on its site the part of the Biofonderie Paris Bioconvergence dedicated to scaling up and relations with industrial projects, as well as the use of different chassis from those used at the Biofonderie Sorbonne University.

Christophe Lanneau

in charge of the Industrial Biofoundry and Director of the Department of Research and Platforms at Genopole

Jean-Loup Faulon

in charge of the Galaxy SynBioCAD digital platform that will pilot the Biofoundry, and Director of Research at the MICALIS lab at INRAe

The Digital Management Platform and Cell-Free Biofoundry

All the Biofoundry sites will be robotized and controlled by an agile, open source and AI-enhanced software solution provided by Jean-Loup Faulon at the MICALIS institute. The IT tools and the database will be managed by MICALIS and shared by all the sites.

The MICALIS Lab is also developing the branch of the biofoundry responsible for production in acellular systems, the Cell-Free Biofoundry.

Consult our data protection policy

Address:

DIM BioConvS

Faculté des Sciences - Université Paris Cité

5 rue Thomas Mann 75013 Paris